Key features/benefits

Description

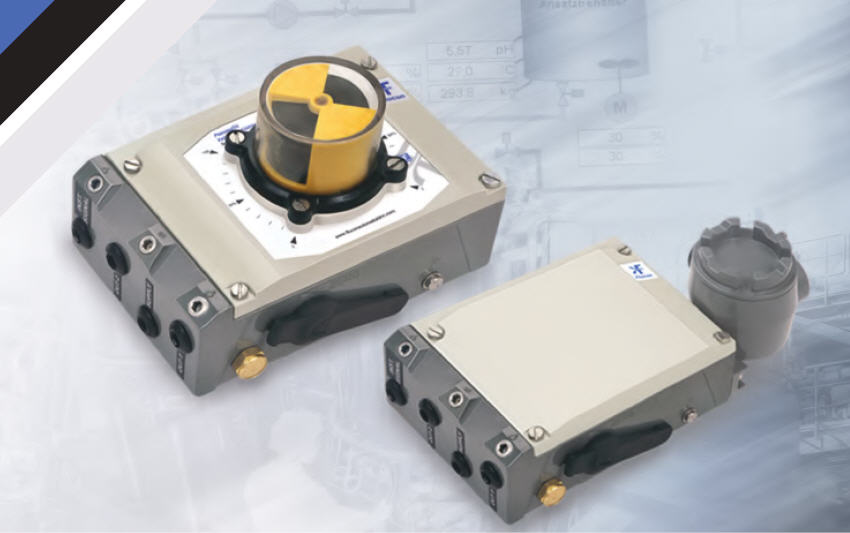

The Flucon FC600 Explosionproof I/P (current to pressure) transducer converts a 4–20mA electrical current signal to a proportionally linear pneumatic output.

The unique conversion technology utilizing open loop control provides a high level of accuracy and repeatability for the operation of actuated valves. A low mass control circuit provides consistent output in high vibration applications.

This compact unit is housed in an explosion proof enclosure that is designed for pipe, bracket or direct manifold mounting. This explosion-proof and intrinsically safe field device is available with an integral volume booster or as a low-flow signal converter that directly mounts to a pneumatic valve positioner.

Principle of Operation

The input current flows through the coil thereby magnetizing the soft-iron yoke. The flux lines of this system being exposed at the gap apply a force

proportional to the input signal on the permanent magnet which is made from a highly coercive metal .

The small magnet together with the flapper forms the moving parts, controlling the air pressure at the nozzle, which is proportional to the magnetic force. The air flowing from the nozzle forms a restoring force balanced by the force applied to the magnet.

The nozzle is supplied with air through a throttle. And back pressure through power amplifier gives proportional output. The described units are properly matched, Hence, a linear correspondence of electric input and pneumatic output signals is achieved.

The direction of action of the converter is determined by the coil polarization.

Zero adjustment is made by twisting the tensioning band, on which the flapper is mounted.

Range adjustment is performed using the potentiometer connected with a resistor in parallel to the coil.