Manual Actuators

Manual actuators rely on human effort to operate mechanical systems. Unlike automated actuators, which use electrical, hydraulic, or pneumatic power, they depend on manual force. They are commonly used in valves, dampers, doors, and other equipment across industries such as ... Read More

-

Manufacturers

-

Industries

-

Body Material

-

Position Indicator

-

Design Standards

-

Motion

-

Failsafe

-

Limit Switch

-

Actuator Technology

-

Protection Classes

-

Actuator Type

-

Country

-

Cast Iron

Cast IronDual Bevel Gearbox (DBG)

Dual Products International South Africa CC -

AIuminium

AIuminiumEDG De-Clutchable Gearbox

Elger Controls India -

Ductile Iron (Cast SG Iron)

Ductile Iron (Cast SG Iron)EGB Bevel Gearbox

Elger Controls India -

Cast Iron

Cast IronEGWC Worm Gearbox

Elger Controls India -

Ductile Iron (Cast SG Iron)

Ductile Iron (Cast SG Iron)EGWS Worm Gearbox

Elger Controls India

Category Description

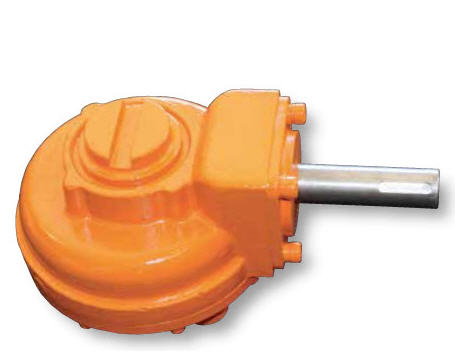

Manual actuators rely on human effort to operate mechanical systems. Unlike automated actuators, which use electrical, hydraulic, or pneumatic power, they depend on manual force. They are commonly used in valves, dampers, doors, and other equipment across industries such as oil and gas, water treatment, and HVAC.

A manual actuator typically includes a handle, gear mechanism, and sometimes a lever or wheel to adjust the position of a valve or control system. Operators can manually open or close valves, regulate flow, or make adjustments without the need for power. These actuators provide a straightforward and reliable way to operate equipment, especially when electricity or pressurized fluids are unavailable.

Manual actuators are simple and cost-effective. They are ideal for situations that require occasional operation but not continuous, high-speed movement. These actuators are durable, easy to use, and provide backup control when automation is not necessary.