Float Valves

Float valves are essential components in various fluid control systems, used to regulate the flow of liquids based on their level. In the oil and gas industry, these valves play a crucial role in maintaining the correct liquid levels in ... Read More

-

Manufacturers

-

Industries

-

Body Material

-

Design Standards

-

ANSI / ASME Ratings

-

Country

-

Actuation Method

-

Media

-

Applications

-

Cast IronWaterWater Treatment

Cast IronWaterWater TreatmentAngle Float Valve PN10-16

-

Cast IronWaterWater Treatment

Cast IronWaterWater TreatmentFloat Valve PN10-16

Category Description

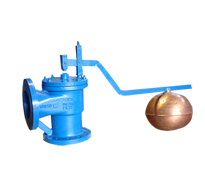

Float valves are essential components in various fluid control systems, used to regulate the flow of liquids based on their level. In the oil and gas industry, these valves play a crucial role in maintaining the correct liquid levels in tanks, vessels, and pipelines, preventing overflows or dry running. Float valves work by using a buoyant float that rises or falls with the liquid level. When the liquid reaches a certain height, the float activates the valve to either open or close, controlling the flow of liquid in or out of the system.

These valves are widely used in storage tanks, sump pumps, and other applications where consistent liquid levels are critical. Float valves are designed to be reliable and durable, often with corrosion-resistant materials to withstand harsh conditions, particularly in oil and gas operations. They are available in various sizes and designs, including manual and automatic models, to suit different applications and system requirements.

Proper maintenance of float valves is crucial to ensure they function correctly and provide accurate liquid level control, contributing to the overall efficiency and safety of industrial systems.