Key features/benefits

Production Range:

API6D ASME/ANSI 150 up to 2500 Lb API6A from API 2000 up to API 15000 Available in SHORT, VENTURI or REGULAR Pattern.

DN 1/2” to 48” Class: up to 600

DN 1/2” to 36” Class: up to 900

DN 1/2” to 24” Class: up to 1500

DN 1/2” to 20” Class: up to 2500

DN 1 13/16” to 7 1/16” Class API 2000 to 15000 Psi

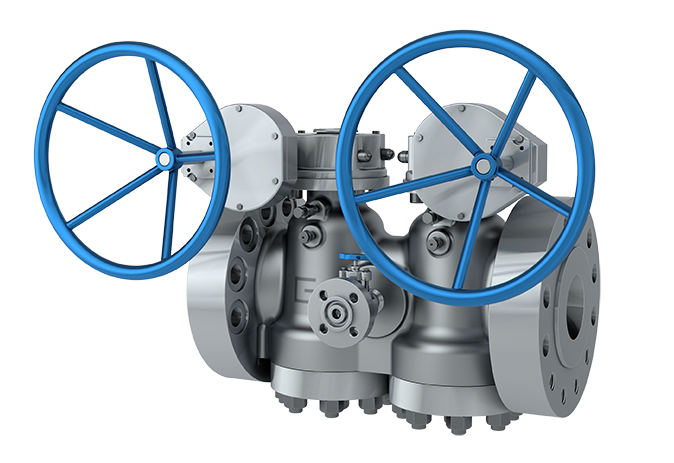

Operator:

Manual Gear or Wrench Operated; Electric Actuator, Pneumatic/Hydraulic actuator single or double acting; Gas Over Oil; Electro Hydraulic

Main Applications:

- Critical bypass, vents, drains and blow-downs to atmosphere

- Compressors & Pumps Isolations

- Water/Slurry/Gas Injection system isolation

- Any critical “Full ΔP” operation