Key features/benefits

Low Emission Valves that Meet ISO 15848-1 Standards

Since the introduction of the U.S. Clean Air Act in 1963, the U.S. Environmental Protection Agency (EPA) has set increasingly stringent guidelines regarding fugitive emissions from industrial facilities in general, and from valves in particular. Typically, valves attribute 50% to 60% of methane emissions in a refinery plant, and 80% are associated with a valve stem leak.

Unlike valve body and flange static seals, the stem seal must function properly in a dynamic environment. It has to endure cycle load, thermal expansion, corrosive conditions, pressure fluctuation, and side loads.

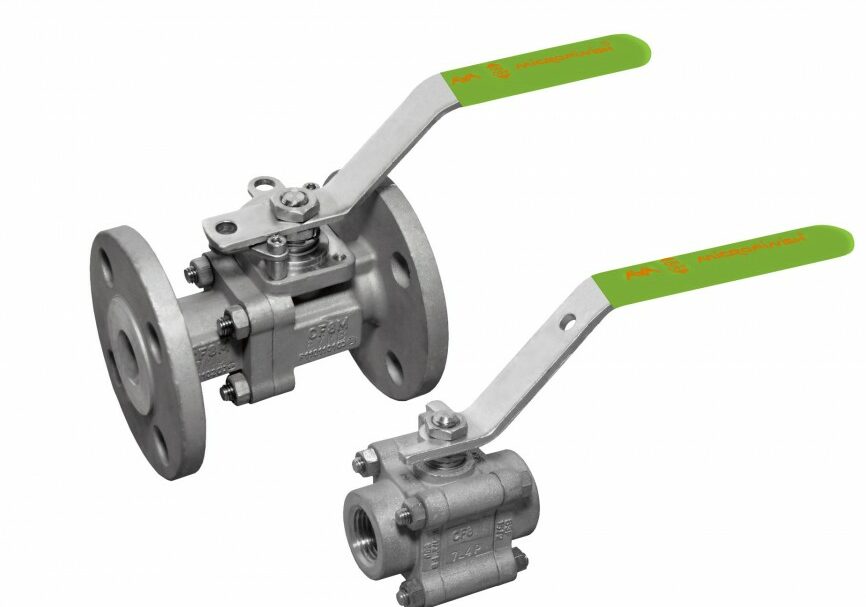

Microfinish concentrated its R&D effort on low emission (Low ‘E’) design performance of its floating and trunnion mounted ball valves. The efforts resulted in a proven live loaded ‘Cup and Cone’ stem packing which successfully passed the stringent requirements of the ISO 15848-1 standard for fugitive emissions and also the API 641 standard requirements.

This enhanced quality feature is just one more factor that permits Microfinish to offer the industry a three year warranty on all floating and trunnion mounted ball valves.