Key features/benefits

Gate valve ECOLINE GTC 150-600 to ANSI/ASME with flanged ends, cast steel A216 WCB, Trim 8 (Stellite/13 % chrome steel) for Class 150/300/600, Trim 5 (Stellite/Stellite) for Class 600, with bolted bonnet, outside screw and yoke, non-rotating stem, flexible wedge, graphite gland packing, stainless steel/graphite gaskets.

Main Applications

- Boiler feed applications

- Fossil-fuelled power stations

- Petrochemical industry

- Refinery

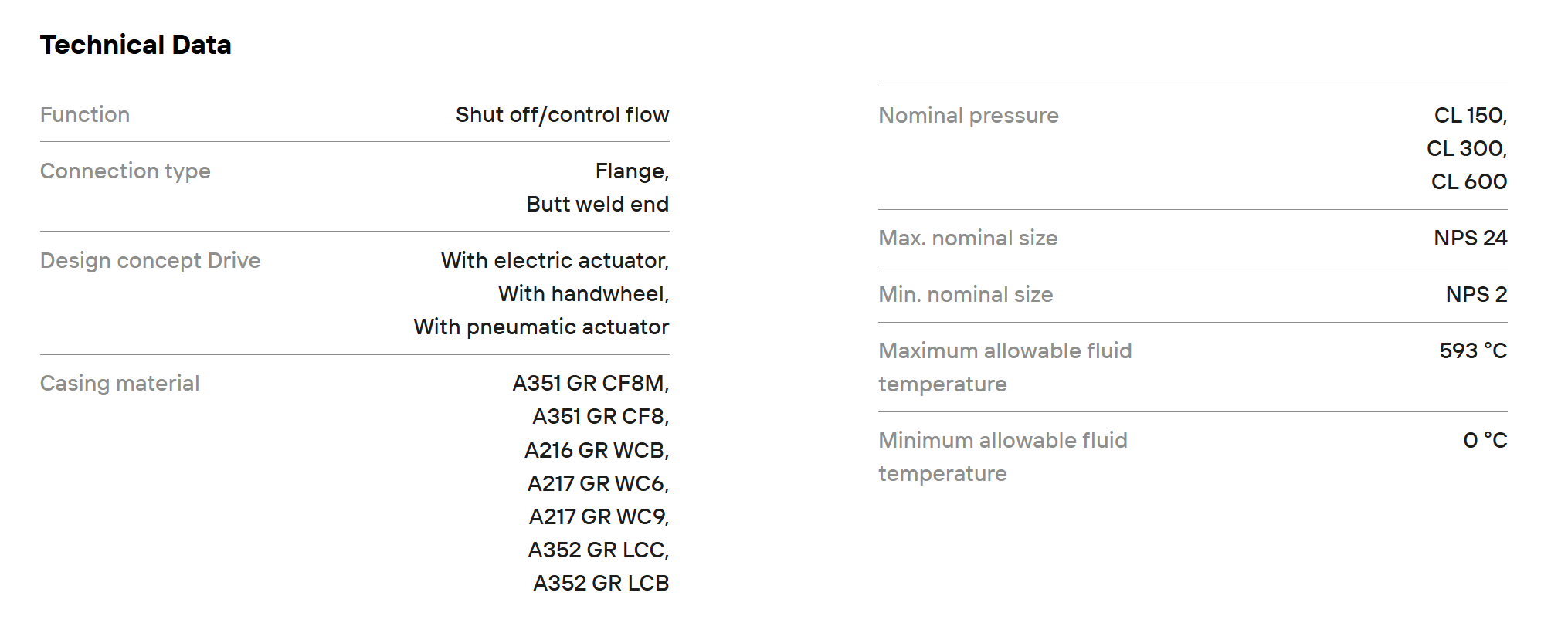

Technical Data

Nominal pressure: CL 150, CL 300, CL 600

Max. nominal size: NPS 24

Maximum allowable fluid temperature: 593 °C

Benefits

- Stem with burnished shank for long service life and high functional reliability of the gland packing

- Hard-faced body seat and solid sealing surface of flexible wedge made of wear-resistant and corrosion-proof materials for reliable sealing and longer service life.

- Two-piece self-aligning gland follower ensures even compression of packing rings.

- Packing end rings of the graphite gland packing enable higher compressive force by gland follower and prevent extrusion of middle graphite packing rings.

- Serrated bonnet gasket fully confined to prevent creep, for reliable sealing

- (Class 150: flat body/bonnet interface due to square or oval flange design to comply with limited face-to-face length specified by design standard).

- Additional safety and blow-out protection by standard back seat.

- Stem nut free from non-ferrous metals, for versatile application.

- Extended maintenance-free service life

- Hard-facing applied to valve disc and seat rings by deposit welding provides extra wear allowance.

- Integral seating surface