Key features/benefits

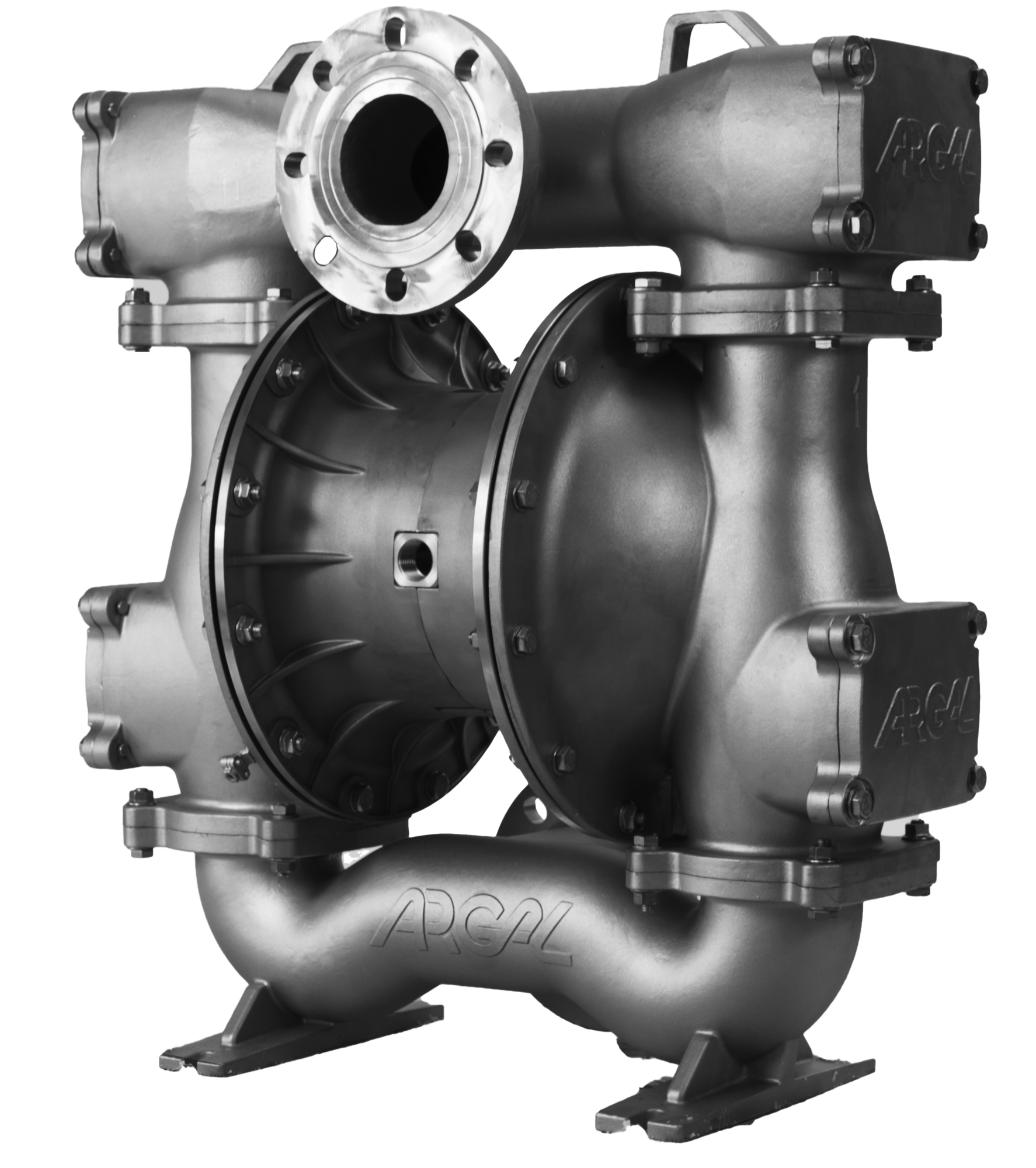

ASTRAsolid (DDS) pumps share the same constructive and performing advantages as ASTRAevo pumps: a fast pneumatic exchanger increased unloading systems for performance optimization (without interfering on air consumption), and an optimized internal design for viscous and loaded liquids. They are made of UHMW-PE solid-block and available in size 1/2″ – 1″ – 1 1/2″ – 2″.

Why offering UHMW-PE solutions? ASTRAsolid pumps are not substituting but completing our current ranges. Thanks to the Ultra High Molecular Weight Polyethylene made from solid-block, ASTRAsolid pumps ensure a very high abrasion and corrosive resistance. They can operate continuously in in- or outdoor applications (with low temperature) and into explosive atmospheres (Ex-proof Zone 2).

- Very high performance

- Optimized air consumption

- Evolved diaphragm caps

- Free-ice system that also increases the performance and keeps the air consumption low

- Optimized internal design for easing the transfer of viscous and charged liquids.

- Very-fast pneumatic exchanger

- Improved operating sensitivity (from 1 bar)

- Non-stalling

- PE1000: highly resistant material with low-friction coefficient and temperature range from -40°c to 70°c.

- modified PTFE diaphragms inert to chemical agents

- Diaphragms available in thermoplastic rubber (TPE, TPV) and reinforced elastomers (FKM, EPDM, NBR)

- Ergonomic fixing

- Easy maintenance

- Ideal for shear sensitive liquids

- Dry-running

- Self-priming

Standard connexions

Various connexions are available upon request

Applications

ASTRAsolid pumps are ideal solutions for transfer operations of abrasive, corrosive and charged liquids.

- Ceramic industry

- Metal and precious metal treatments

- Water and wastewater treatments

- Seawater and corrosive applications

- Heavy-duty applications with abrasive agents