Key features/benefits

- High hydraulic performance up to 715 l/min

- Optimized air consumption

- Evolved diaphragm caps

- Non-icing air valve system

- Operating sensitivity improved (from 1 bar)

- Integrated muffler up to model DDE 160

- Easy maintenance

- Ideal for shear-sensitive liquids

- modified PTFE diaphragms inert to chemical agents

- Diaphragms available in thermoplastic materials (TPE, TPV) and reinforced elastomers (FKM, EPDM, NBR)

- Dry-running

- Self-priming

- Upon request: FDA conformity with ASTRAevo FOOD version

- Upon request: ATEX Zone 2 (II 3G Ex h IIB T4 Gb X | II 3D Ex h IIIB T135°C Db X) and Zone 1 (II 2G Ex h IIB T4 Gb X | II 3D Ex h IIIB T135°C Db X) with conductive body and parts

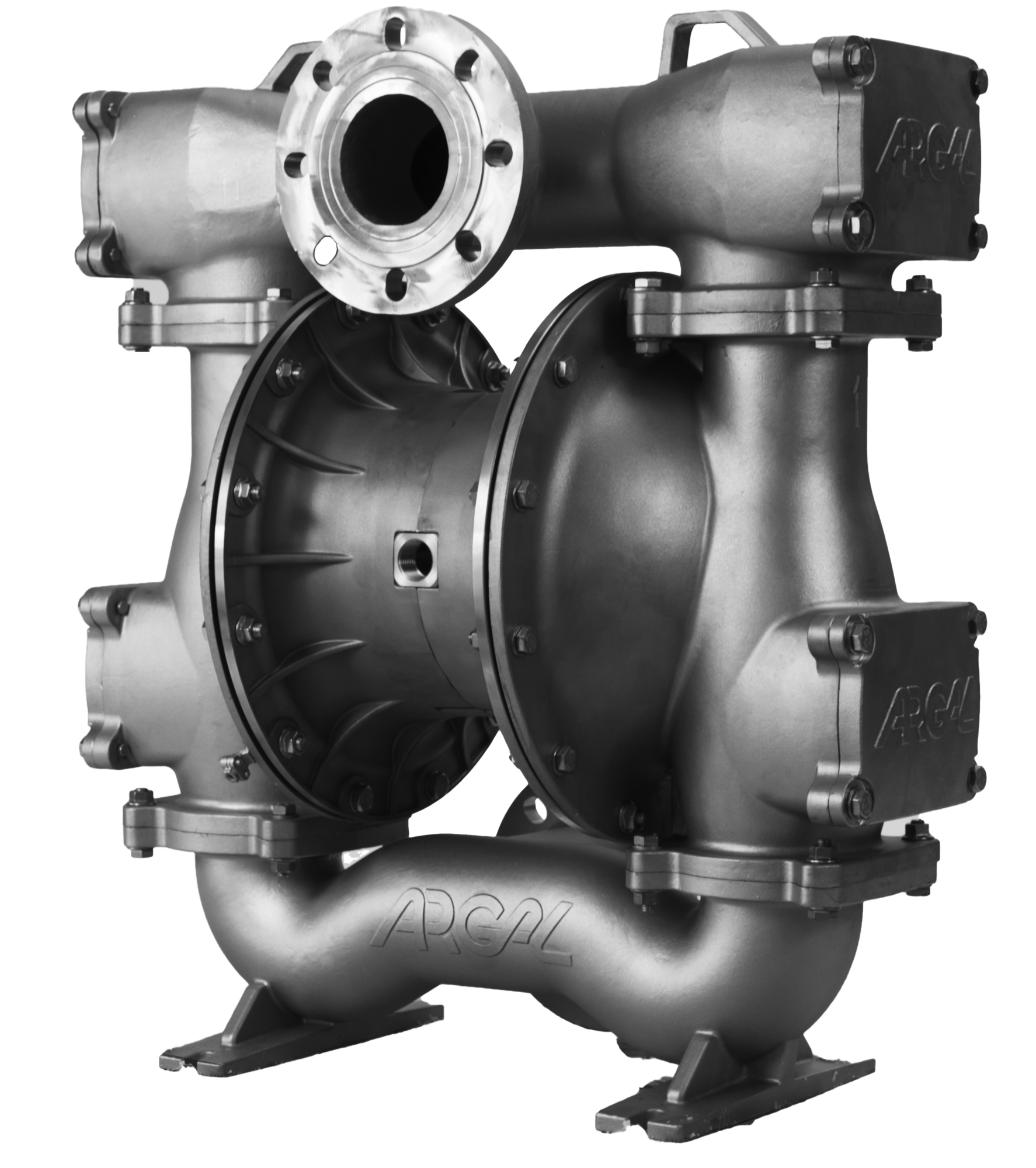

Overview

.png)

Internal composition

Standard connections

Upon request: all connection configurations are available for plastic and aluminum versions.

- AISI 316l versions can be set with the connections up to model DDE 160. Models DDE 400 and DDE 650 have the flanged connections “F-B”

- It is not possible to set the “F-B” connections and “V” connection is not recommended for model DDE 020

For further connection configurations, contact us

Applications

- Chemical production

- Surface treatment

- Water and wastewater treatment

- Aerospace

- Pulp and paper

- Automotive

- Flexographic

- Pharmaceutical

- …