Key features/benefits

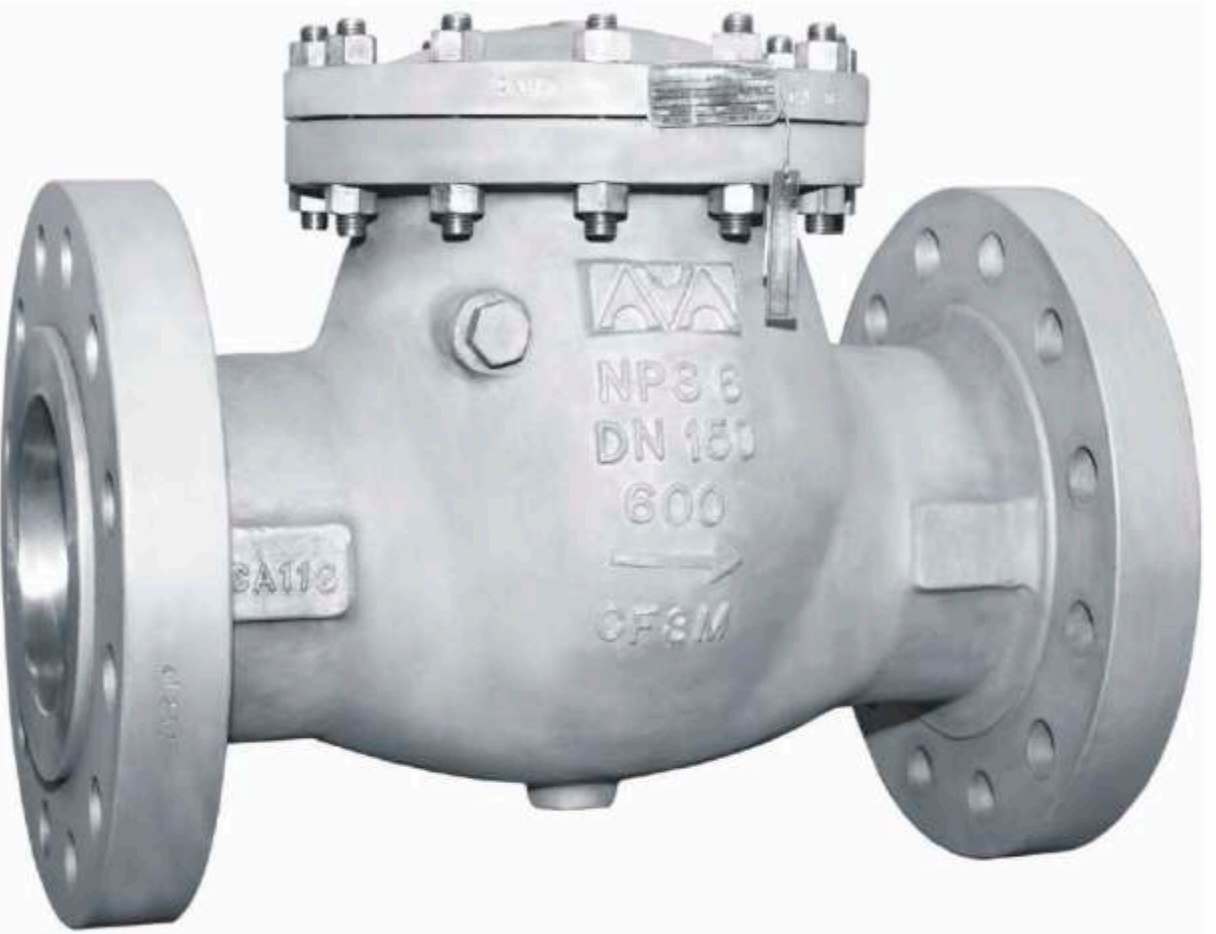

Valves for Chlorine Service

Microfinish valves for dry chlorine service are in full compliance with the guidelines established in the chlorine institute, Pamphlet 6: “Piping Systems for Dry Chlorine”.

The valve body material is made from carbon steel WCB, LCB or LC1 (for low temperature), and trim made of Alloy C22 or Alloy C276 material. Microfinish chlorine service valves are cleaned, assembled, tested, packed and delivered under the same conditions of valves used for oxygen service.

In cases where there is a risk of uncontrolled cavity pressure build up due to media phase change, Microfinish chlorine valves will include a ball with the relief hole facing the upstream side.