Key features/benefits

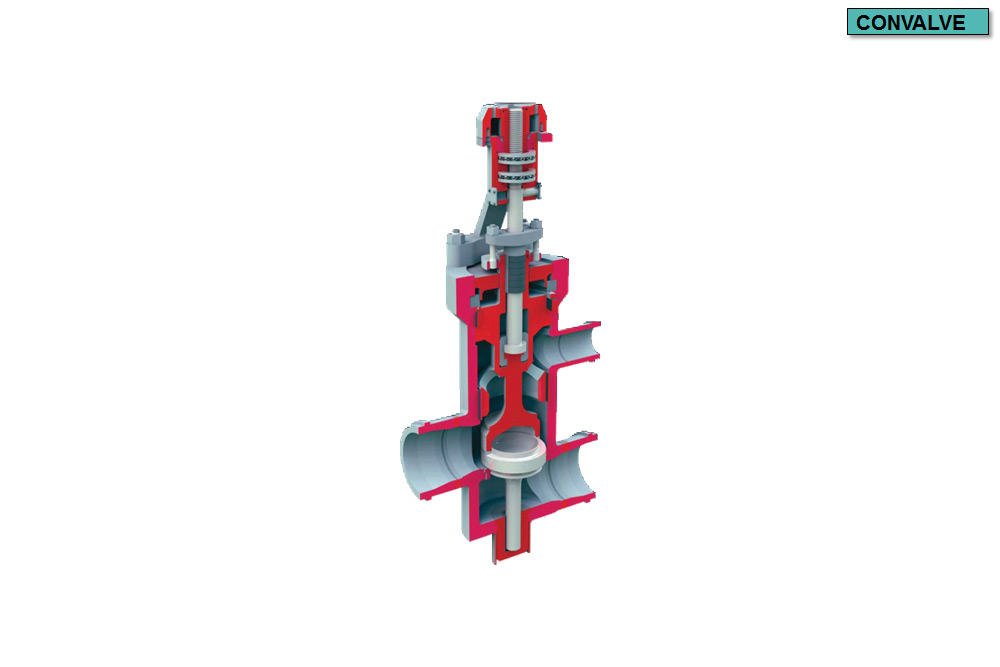

With the triple offset butterfly valve there are three offsets. Two are placed in a similar position to the double offset butterfly valve, while the third offset is the geometry of the seating surface, creating a type of cone shape of the disc and seat. This cone angle, along with the two eccentric shaft offsets, allows the disc to seal against the seat with no friction.

This seat design also allows for uniform sealing, and thus a tight shutoff in a metal seat design. This design is a lower cost, lower torque option (easier to automate), than alternative style metal seated valves.

Features

- Metal to metal sealing

- Triple eccentric quarter-turn design

- Torque seated

- Bi-directional tight shutoff

- Zero leakage

- Non-rubbing seating

- Inherently fire safe and fire tested

Applications

- Process fluids

- Hydrocarbons

- Steam/Geothermal steam

- Hot gas/Sour gas (NACE)

- Oxygen, Hydrogen

- Blow down

- Sulfur recovery

- Acid, Caustic, Chloride

- Abrasive service

Temperature Limits

- From -196°C (-320°F) up to +818°C (+1600°F)

Pressure Limits

- From Full Vacuum up to +450 Bar (2200 psi)

Production Range

- ND 2″ – 160″ ANSI Cl. 150

- ND 2″ – 80″ ANSI Cl.300

- ND 3″ – 80″ ANSI Cl. 600

- ND 6″ – 48″ ANSI Cl. 900

- ND 6″ – 24″ ANSI body in ANSI Cl. 1500

- ANSI Cl. 2500 with ANSI Cl.900 trim

Body Style

- Double flanged ISO 5752

- Double flanged ANSI B 16-10 (gate)

- Wafer & Lugged API 609

- Butt-Weld.

Rating

- NP 6-10 – 16 – 25 – 40 – 64 – 100

- ANSI Cl. 150 – 300 – 600 – 900 – 1500 – 2500

Materials

- LCB, LC3

- Duplex

- Superduplex

- Monel

- Hastelloy

- 254 SMO

- Alloy steel WC6, WC9

- Inconel

- Alloy 20

- Aluminium Bronze

- Titanium.

Aplicable Standarts

- Design: ANSI B16.34 / ASME VIII

- Face to face: API/ISO/ANSI

- Flange: ANSI/ISO/DIN/UNI/JIS

- Testing: ZERO leakage

- Fire Test: BS 6755 – API 607 fourth Ed.

Design Standarts

- Design & Manufacture: ANSI16.34,BS 5155,JIS B2071,DIN 3354.

- Face-to-face Dimension: API 609, ISO 5752,DIN 3202,BS 4504,JIS B2002 .

- Flanged Ends: ANSI B16.5, MSS-SP-44, ISO 7005 ,BS 4504.

- Butt-weld Ends: ANSI B16.25.

- Pressure Test: API 598, ISO 5208, BS 5146.

Principle Of Operation

The Convalve Triple Offset Butterfly Valve provides a bi-directional bubble tight shut-off. This geometry ensures that the disc seal contacts the body

seat only at the final shut-off position without rubbing or galling, providing a torque generated resilient seal with sufficient “wedging” to ensure a uniform seal contact.

The Triple Offset Geometry

OFFSET 1 The shaft is offset behind the seat axis to allow complete sealing contact around the entire seat.

OFFSET 2 The shaft centerline is offset from the pipe and valve which provides interference free opening and closing of the valve.

OFFSET 3 The seat cone axis is offset from the shaft centerline to eliminate friction during closing and opening and to achieve uniform compressive sealing around the entire seat.